Welcome to Leader in Component Manufacturing since 1985

Phone: +91 - 22 - 26208929 | Email: [email protected]

Welcome to Leader in Component Manufacturing since 1985

Phone: +91 - 22 - 26208929 | Email: [email protected]

Crown molding has long been a hallmark of elegance and sophistication in interior design. This architectural feature, placed at the junction of walls and ceilings, adds a finishing touch that elevates the character of any room. Traditionally, crown molding has been associated with classical or ornate interiors, but its appeal transcends design eras, making it a versatile choice for both modern and traditional homes. For woodworkers and DIY enthusiasts, crafting custom crown molding using router bits is a rewarding way to achieve a tailored, professional look while adding a personal touch to a project.

Creating crown molding with router bits opens up a world of design possibilities. Instead of relying on pre-made moldings that may not perfectly match your vision, you have the ability to craft pieces that are entirely unique. This level of customization allows for the creation of intricate profiles that can be as simple or ornate as desired, blending seamlessly with the overall design of the space. Router bits specifically designed for crown molding make this process accessible, even for those new to woodworking, providing both precision and creativity in one tool.

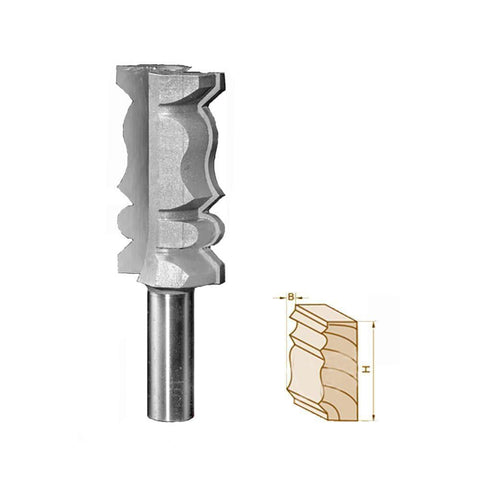

Router bits used for crown molding are typically larger than standard bits, designed to handle the deeper cuts and more complex profiles needed to shape molding. These bits are often referred to as crown molding bits or profile bits, and they come in a variety of styles to create different contours and decorative details. With these bits, you can produce traditional ogee curves, sharp angles, or even more elaborate shapes that mimic historical molding styles. The versatility of these bits is one of their greatest advantages - they allow you to craft molding that perfectly complements the architectural features of the room, whether you're aiming for a minimalist design or a more elaborate, layered look.

One of the major benefits of making your own crown molding with router bits is the control it offers over the size and scale of the molding. Off-the-shelf crown moldings are available in standard sizes, but custom homes and unique spaces often require non-standard dimensions. By using router bits, you can create molding that is perfectly proportioned for your space. This flexibility is particularly useful in older homes with non-standard ceiling heights or in rooms where the scale of the architecture calls for something more dramatic or understated. With the right bit, you can match the exact height, depth, and angle of the molding to suit the room's proportions.

When creating crown molding, the material choice is also critical, and router bits allow you to work with a range of materials, from hardwoods to softwoods to composite materials. For formal rooms or areas where you want to highlight craftsmanship, hardwoods like oak, cherry, or walnut offer a rich, natural beauty that enhances the molding's design. Softer woods like pine or MDF are more cost-effective and easier to work with, making them ideal for painting or rooms with a more casual feel. The sharpness and durability of router bits are key to achieving clean, crisp edges regardless of the material, ensuring the molding looks professionally finished.

Precision is another key advantage of using router bits for crown molding. These bits are designed to cut profiles accurately, ensuring that each piece of molding is consistent from one section to the next. This is particularly important when installing molding along lengthy walls or throughout a large room where any variation in profile would be noticeable. Router bits, when used properly, help to maintain that uniformity, reducing the need for additional sanding or touch-ups after the pieces are cut. This level of precision is what gives custom-made crown molding its professional edge, creating seamless joins and perfect lines that are difficult to achieve with pre-manufactured moldings.

Beyond the aesthetic appeal, crafting crown molding with router bits also provides cost savings. Purchasing large quantities of pre-made molding, especially in custom sizes, can be expensive. However, by using router bits and raw materials, you can create your own crown molding at a fraction of the cost. This is especially beneficial for large projects or entire home renovations where the cost of trim and molding can quickly add up. Additionally, being able to make adjustments or changes to the design without waiting for custom orders adds efficiency to the process, allowing for faster project completion.

For woodworkers and hobbyists, there is a deep satisfaction in creating something from scratch, and making crown molding with router bits is no exception. The craftsmanship involved in shaping and detailing the molding adds a personal touch to the home, transforming a simple space into something special. The ability to customize profiles means that the molding can reflect the unique character of the home and its inhabitants, whether through subtle, clean lines or intricate, ornate detailing.

Router bits designed for crown molding give woodworkers the power to create custom, elegant trim work that enhances any space. The precision, versatility, and cost-effectiveness of this approach make it an attractive option for those looking to add architectural interest to their homes. With the right tools and a bit of creativity, anyone can produce stunning, professional-grade crown molding that adds lasting beauty and value to a room.