Welcome to Leader in Component Manufacturing since 1985

Phone: +91 - 22 - 26208929 | Email: [email protected]

Welcome to Leader in Component Manufacturing since 1985

Phone: +91 - 22 - 26208929 | Email: [email protected]

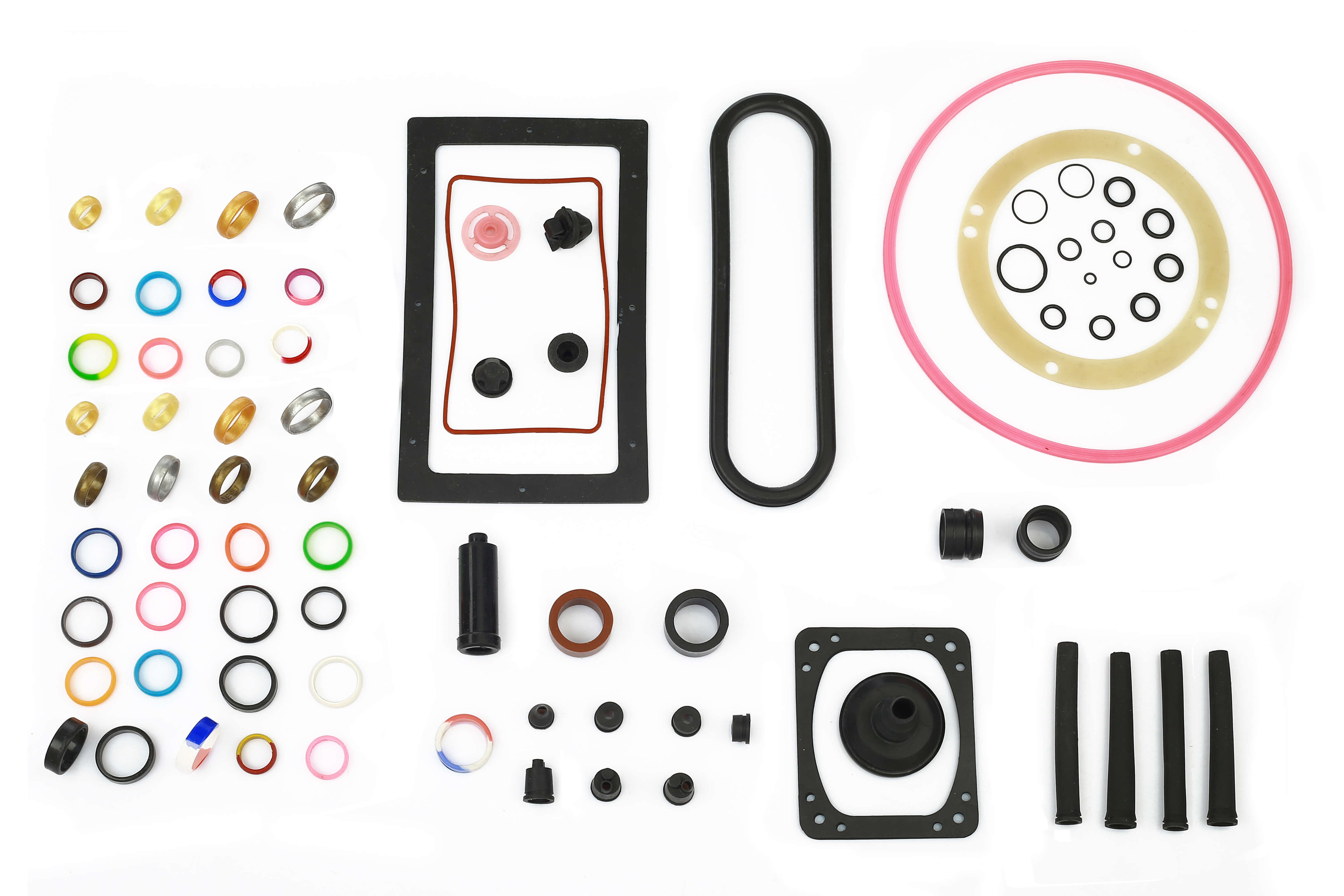

We at CONTOUR ENGINEERS an ISO 9001:2015 certified company are a specialized engineering team. We provide various multinational companies all over the World a wide range of products. It is in this striving for excellence that helps us to produce international quality products.

Our president Mr. Mehul Thacker with Mechanical and Electrical engineering background has worked for 2 decades in German MNC with an experience in R& D, Production & cost reduction areas. Know more

We have developed several components for overseas industries winning confidence of our customers.

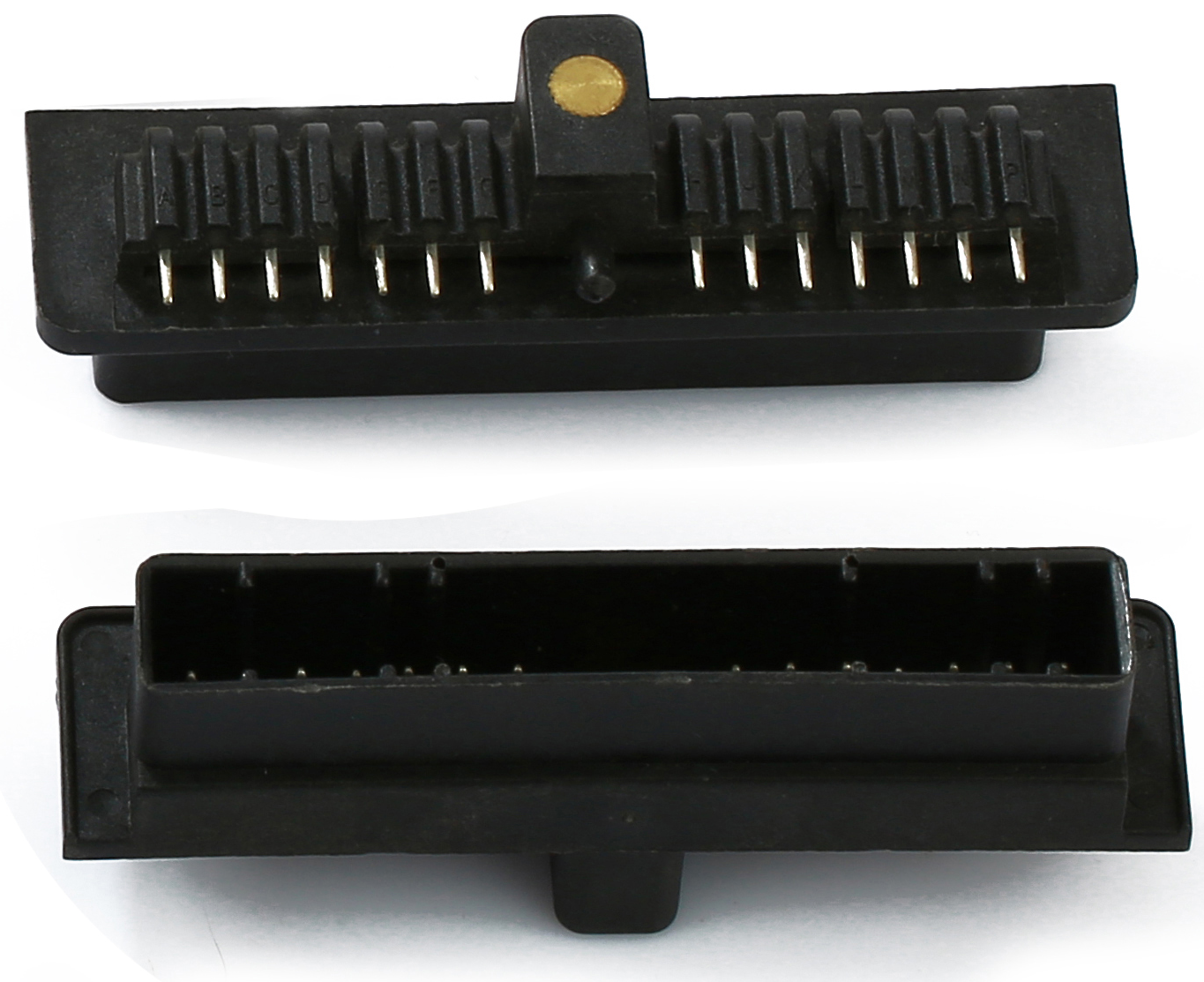

Precision molded male female connectors from high heat resistant Ultem material with gold plated brass pins are used in various industries for electrical connections in high temperature environment.

PCB mounted 14 pin connector used in Automobile industry is highly precision molded part with tin plated solderable copper pins.

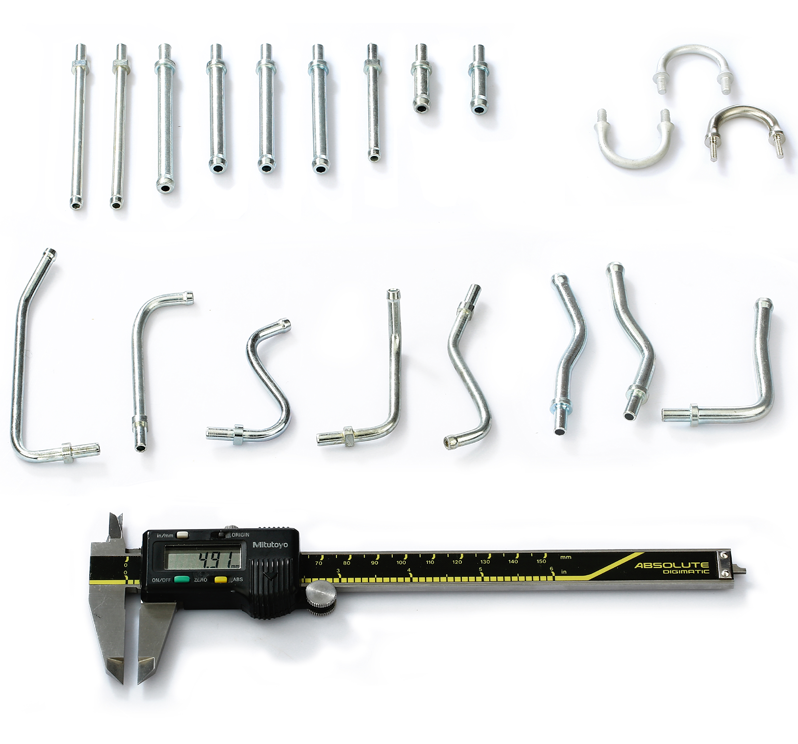

We can supply a variety of tubular bends. The facility has a wide range of tube bending capabilities which can produce nearly any tube bend per your requirement. Tubes shown in the picture are bent tubing as custom shaped. The tubes are CNC turned and machined before bending.

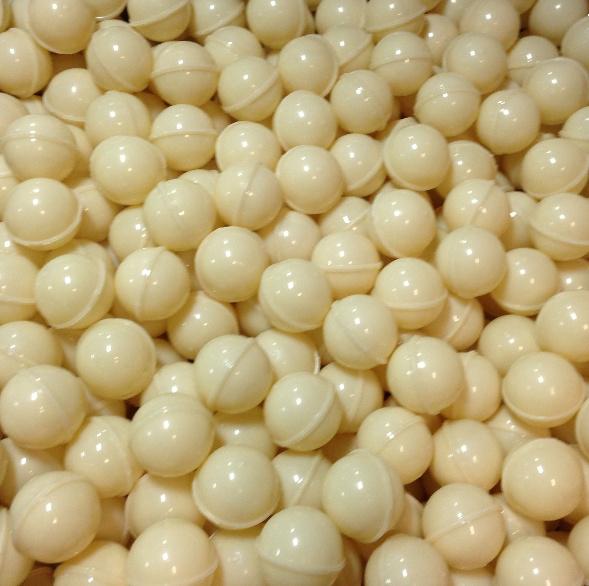

Precision molded and ultrasonically welded leak proof 50 mm dia. spheres are used in marine buoys for underwater application. Each sphere has an imploding strength of 100-110 bar.

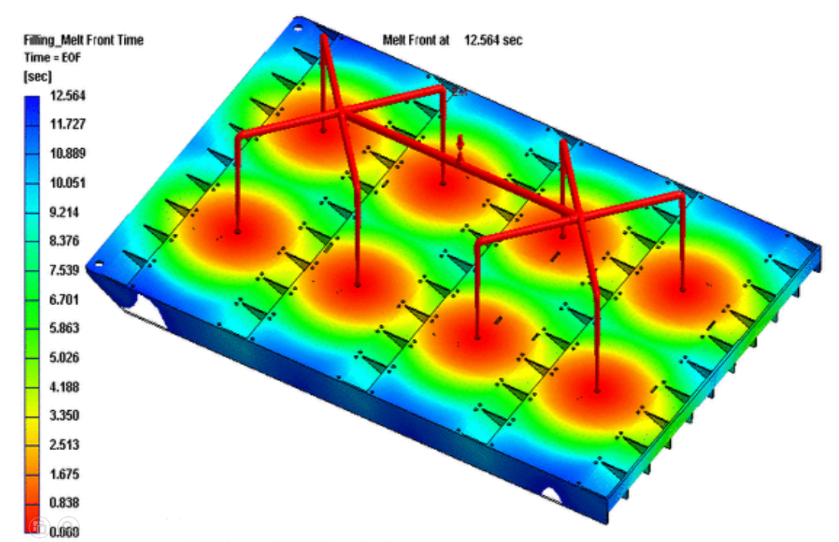

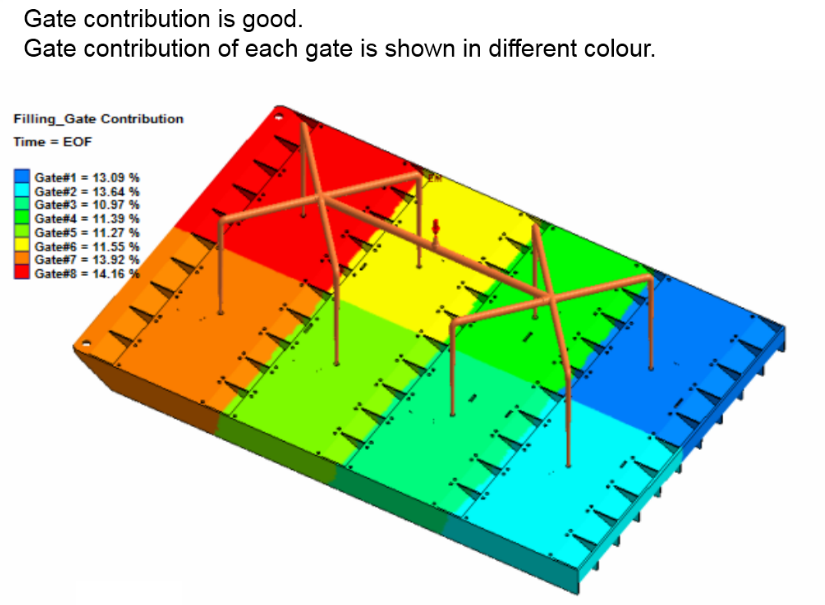

The largest part of 900 x 600 mm of Giant Board weighing 2.5 Kg. has a typical application under water. The board is processed on 1000 Ton clamping force capacity injection molding machine. The part is developed after detailed mold flow analysis to achieve the best quality from a hot runner system injection mold. The picture shows top and bottom view of this part made out of special grade of Polypropylene.

Rapid Prototyping has become the greatest advanced technology in time savings. Even from the most complex design, we can make a cost effective, 3-D stereolithography model. Rapid prototyping is perfect for master patterns for fast turnaround for producing plastic parts in thermoplastic resins or urethanes.